Umatshini wokuWelding weNdawo yokuGcina Amandla

Umatshini wokuwelda indawo yokugcina amandla sisixhobo esisebenzisa i-capacitors yokugcina amandla ukukhupha ubushushu kunye nokufezekisa udibaniso lwe-welding yeendawo zentsimbi. Isetyenziswa kakhulu kwimimandla efana nokuveliswa kweebhetri, izinto ze-elektroniki, kunye neendawo zeemoto.

| Umlinganiselo wokuthelekisa | I-Energy Storage Spot Welder | Traditional AC / DC Spot Welder |

| Umthombo wamandla | Ukukhutshwa kwe-capacitor yokugcina amandla (uhlobo lwe-pulse): Igcina amandla ukusuka kwigridi ukuya kwii-capacitors ngokutshaja okucothayo kunye nokukhupha amandla athambileyo ngoko nangoko ngexesha le-welding. | Unikezelo lwamandla egridi ethe ngqo (uhlobo oluqhubekayo): Itsala amandla kwigridi ngokuqhubekayo ngexesha le-welding, ixhomekeke kumbane wegridi ozinzile. |

| Ixesha leWelding | I-Milisecond-level (1–100 ms): Igqibezela ukuwelda ngexesha elifutshane kakhulu ngegalelo lobushushu eliphantsi kakhulu. | Amakhulu eemilliseconds ukuya kwisekhondi: Inkqubo yewelding ecothayo kunye nokwanda kobushushu obucacileyo. |

| Indawo echatshazelwe bubushushu (HAZ) | Amancinci: Amandla agxininisiweyo kunye nexesha elifutshane lesenzo libangela i-welds encinci kunye ne-deformation encinci ye-thermal, efanelekileyo kumacandelo achanekileyo. | Okukhulu: Ukufudumeza okuqhubekayo kunokubangela ubushushu obuphezulu bendawo kwizixhobo zokusebenza, okunokukhokelela kuguquko okanye ukufakwa. |

| Impembelelo yegridi | Phantsi: Uzinzo lwangoku ngexesha lokutshaja (umzekelo, ukutshaja ngezigaba), kunye nexesha elifutshane le-pulsed current ngexesha le-welding ibangela ukuguquguquka okuncinci kwegridi. | Phezulu: Umsinga ophezulu ngokukhawuleza (ukuya kumashumi amawaka e-amperes) ngexesha le-welding inokubangela ukwehla ngequbuliso kumbane wegridi, ifuna inkqubo yokuhambisa amandla ezinikeleyo. |

| Iimeko zeSicelo | Iindawo ezinodonga olunqabileyo (umzekelo, i-0.1-2 mm iifoyile zetsimbi, i-electronic component lead), iimfuno ezichanekileyo (umzekelo, i-lithium ibhetri yethebhu ye-welding), imigca yokuvelisa ezenzekelayo (ehambelanayo kunye neerobhothi ze-welding ezikhawulezayo). | Ukuwelda ipleyiti eshinyeneyo (umzekelo, iipleyiti zentsimbi ngaphezu kwe-3 mm), iimeko zemveliso ezingaqhubekiyo (umzekelo, ukugcinwa, ukusetyenzwa kwebhetshi encinci), kunye nezihlandlo ezineemfuno eziphantsi zesantya sokuwelda. |

Uluhlu olupheleleyo lweHeltec lweSpot Welder

Ibhetri Spot Welder 01 Series

Ibhetri Spot Welder 02/03 Series

Umatshini wokuWelding weLaser

Cantilever Laser Welding Machine

Umatshini wokuWelding weLaser ophathwa ngesandla

Spot welder Accessories-Spot Welding Head

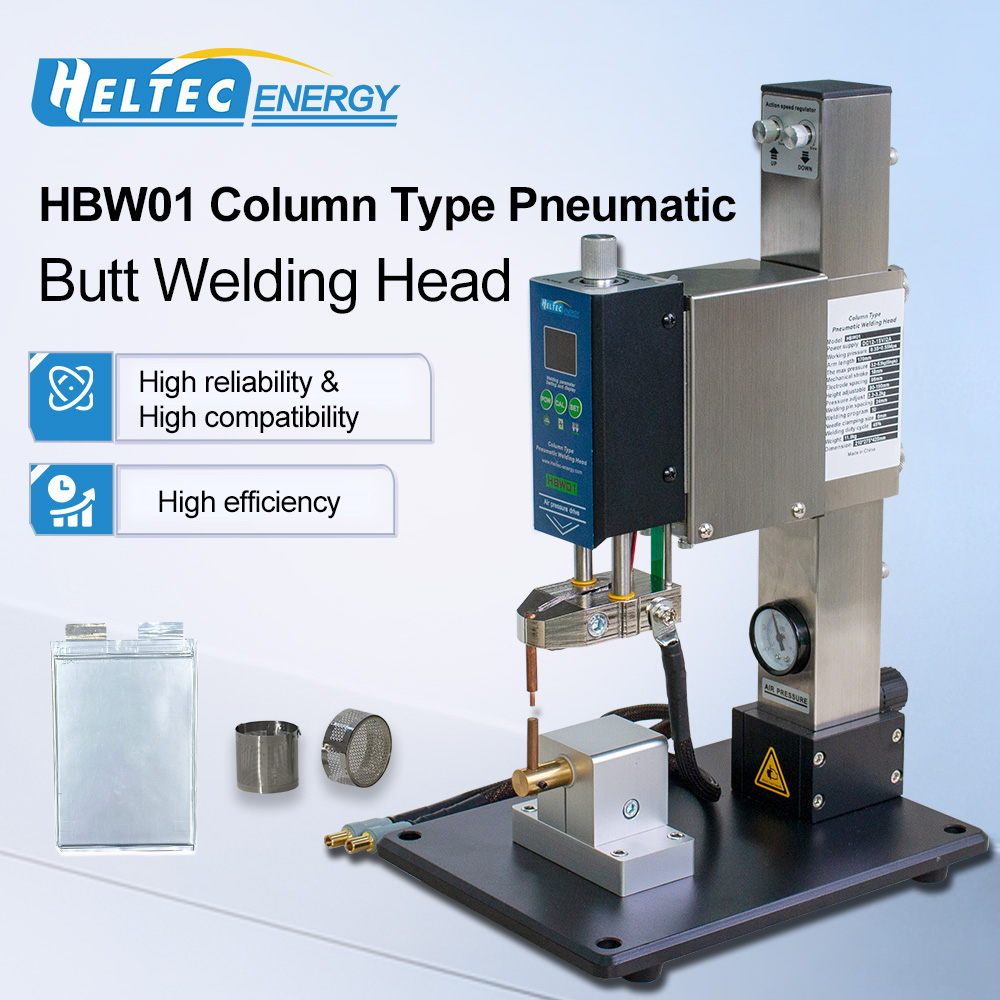

IPneumatic Flat Welding Head

Intloko ye-Pneumatic Butt Welding

Iinzuzo zobugcisa

Ukonga amandla kunye nokusebenza kakuhle:Ukusetyenziswa kwamandla okuphantsi kwangoko ukusuka kwigridi yamandla, amandla aphezulu, impembelelo encinci kwigridi yamandla, kunye nokonga amandla.

Umgangatho olungileyo we-welding:Amanqaku e-welding aqinile, ngaphandle kokuguqulwa kombala, ukonga inkqubo yokupolisha kunye nokusebenza okuphezulu; I-voltage ephumayo izinzile kwaye ine-consistency elungileyo, enokuqinisekisa ukuhambelana kwesiphumo semveliso ye-welding.

Ubomi obude be-electrode:Xa kuthelekiswa noomatshini bokuwelda bendawo, ubomi be-electrode bunokwandiswa ngokuphindwe kabini, ukunciphisa iindleko zokusetyenziswa.

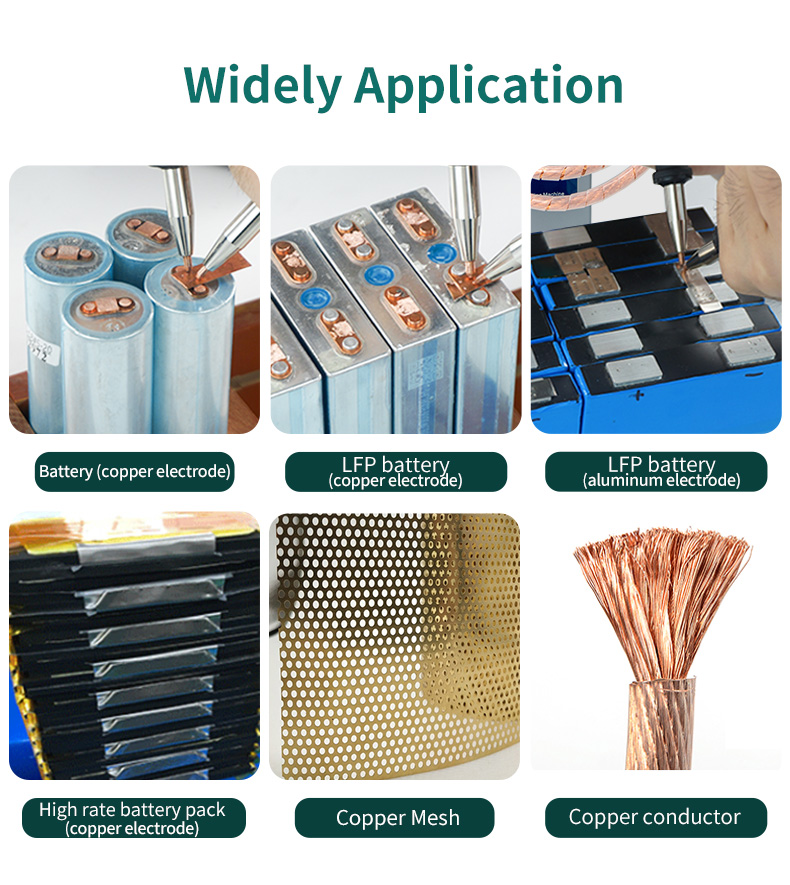

Ukuziqhelanisa ngamandla:Isebenza ngokubanzi kwizixhobo ze-welding, ezifanelekileyo kwiintsimbi ezingenayo i-ferrous kunye ne-alloy materials ezifana nobhedu, i-aluminium, insimbi engenasici, i-nickel, njl. Ukwazi ukuziqhelanisa kakuhle nokusebenza kwamaqhekeza obunzima obuhlukeneyo kunye neemilo.

Itheyibhile yoKhetho lweModeli

| SKU | HT-SW01A | HT-SW01A+ | HT-SW01B | HT-SW01D | HT-SW01H | HT-SW02A | HT-SW02H | HT-SW03A | HT-SW33A | HT-SW33A+ |

| Umgaqo | DC yokugcina amandla | DC yokugcina amandla | DC yokugcina amandla | DC yokugcina amandla | DC yokugcina amandla | DC yokugcina amandla | DC yokugcina amandla | Isiguquli se-AC | DC yokugcina amandla | DC yokugcina amandla |

| Amandla emveliso | 10.6KW | 11.6KW | 11.6KW | 14.5KW | 21KW | 36KW | 42KW | 6KW | 27KW | 42KW |

| Imveliso yangoku | 2000A (Ubuninzi.) | 2000A (Ubuninzi.) | 2000A (Ubuninzi.) | 2500A (Ubukhulu.) | 3500A (Ubuninzi.) | 6000A (Ubuninzi.) | 7000A (Ubuninzi.) | 1200A (Ubuninzi.) | 4500A (Ubukhulu.) | 7000A (Ubuninzi.) |

| Izixhobo ze-Welding ezisemgangathweni | 1.70A(16mm²) ipeni yokuwelda yokwahlulahlula; | 1.70B(16mm²) usiba lwewelding oludityanisiweyo; | 1.70B(16mm²) usiba lwewelding oludityanisiweyo; | 1.73B(16mm²) usiba lwewelding oludityanisiweyo; | 1.75 (25mm²) ipeni yokuwelda yokucanda; | 75A(35mm²) ipeni yokuwelda yokucanda | 1. 75A(50mm²) ipeni yokuwelda yokwahlulahlula | 1.73B(16mm²)ipeni yokuwelda edibeneyo; | Isixhobo sokuwelda indawo yomoya se-A30. | Isixhobo sokuwelda indawo yomoya se-A30. |

| Welding nickel ecocekileyo | 0.1 ~ 0.15mm | 0.1 ~ 0.15mm | 0.1~0.2mm | 0.1~0.3mm | 0.1~0.4mm | 0.1~0.5mm | 0.1~0.5mm | 0.1~0.2mm | 0.15~0.35mm | 0.15~0.35mm |

| I-Nickel plating iwelding | 0.1~0.2mm | 0.1 ~ 0.25mm | 0.1~0.3mm | 0.15~0.4mm | 0.15~0.5mm | 0.1 ~ 0.6mm | 0.1 ~ 0.6mm | 0.1~0.3mm | 0.15~0.45mm | 0.15~0.45mm |

| Welding nickel ecocekileyo | / | / | / | / | / | 0.1~0.2mm | 0.1~0.3mm | / | 0.1~0.2mm | 0.1~0.2mm |

| I-Nickel aluminiyam ehlanganisiweyo yephepha lokuwelda | / | / | / | / | 0.1 ~ 0.15mm | 0.1~0.2mm | 0.15-0.4mm | / | 0.1~0.3mm | 0.1~0.3mm |

| I-Copper welding LFP i-electrode yobhedu (ene-flux) | / | / | / | / | / | 0.1~0.3mm | 0.15~0.4mm | / | 0.1~0.3mm | 0.1~0.3mm |

| Ukunikezwa Amandla | AC 110~220V | AC 110~220V | AC 110~220V | AC 110~220V | AC 110~220V | I-AC 110 okanye i-220V | I-AC 110 okanye i-220V | I-AC 110 okanye i-220V | I-AC 110 okanye i-220V | I-AC 110 okanye i-220V |

| Umbane ophumayo | DC 5.3V(Max.) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) | DC 6.0V(Ubukhulu) |

| UkuTjaja okuGcinwa kwaMandla ngoku | 2.8A(Ubuninzi.) | 2.8A(Ubuninzi.) | 4.5A(Ubuninzi.) | 4.5A(Ubuninzi.) | 6A(ubuninzi.) | 15A(Ubuninzi.) | 15A(Ubuninzi.) | Akukho ntlawulo ifunekayo | 15A -20A | 15A -20A |

| Ixesha Lokuqala Lokutshaja | 30 ~ 40 imiz | 30 ~ 40 imiz | 30 ~ 40 imiz | 30 ~ 40 imiz | Malunga ne-18 min | Malunga ne-18 min | Malunga ne-18 min | Akukho kutshaja okufunekayo, plagi ukuze usebenzise | Malunga ne-18 min | Malunga ne-18 min |

| Imowudi yokuqalisa | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | AT: I-automatic induction trigger | MT: Ukunyovwa ngeenyawo | MT: Ukunyovwa ngeenyawo | MT: Ukunyovwa ngeenyawo |

| I-On-resistance/Nickel Sheet Resistance Measurement Function | × | × | × | × | × | × | √ | × | × | × |

| Voltage Test Umsebenzi | × | √ | × | × | × | × | × | × | × | × |

Indawo yeSicelo seBattery Spot Welding Machine

- Indawo ye-welding ye-Lithium yentsimbi ye-phosphate ibhetri, i-Ternary lithium ibhetri, intsimbi yenickel.

- Hlanganisa okanye ulungise iipakethi zebhetri kunye nemithombo ephathekayo.

- Ukuveliswa kweebhetri ezincinci zezixhobo zombane eziphathwayo

- Ukuwelda kwebhetri ye-lithium polymer, ibhetri yeselula, kunye nebhodi yesekethe ekhuselayo.

- Spot iinkokeli zokuwelda kwiiprojekthi ezahlukeneyo zentsimbi, ezinjengentsimbi, intsimbi, ubhedu, i-nickel, imolybdenum kunye ne-titanium.

Qhagamshelana nathi

Ukuba uneenjongo zokuthenga okanye iimfuno zentsebenziswano kwiimveliso zethu, nceda uzive ukhululekile ukuqhagamshelana nathi nangaliphi na ixesha. Iqela lethu lobuchwephesha liza kuzinikela ekukhonzeni, liphendule imibuzo yakho, kwaye likunike nezisombululo ezikumgangatho ophezulu.

Jacqueline: jacqueline@heltec-energy.com / +86 185 8375 6538

Nancy: nancy@heltec-energy.com / +86 184 8223 7713