Intshayelelo:

Wamkelekile kwiAmandla eHeltecibhlog yoshishino! Njengenkokeli kushishino lwezisombululo zebhetri ye-lithium, sizinikele ekuboneleleni ngezisombululo ezipheleleyo ze-one-stop kubavelisi kunye nababoneleli ngeepakethi zebhetri. Sigxile kakhulu kuphando nophuhliso, kunye nokuveliswa kwezixhobo zebhetri,Amandla eHeltecizimisele ukuxhobisa eli shishini ngokubonelela ngeemveliso kunye neenkonzo ezintsha. Emva kweminyaka yophuhliso, izixhobo zokuwelda iibhetri zihlala ziphuculwa, umgangatho wokuwelda kwiindawo ezithile nawo uhlala uphuculwa. Kodwa sihlala sibona iintlobo ngeentlobo zee-spot welders kwisityalo esinye semveliso kunye, bedlala indima yabo. Siza kuhamba kumgaqo weentlobo ngeentlobo zee-spot welders.umatshini wokuwelda indawoukuqonda ukusebenza kwabo.

Isicelo:

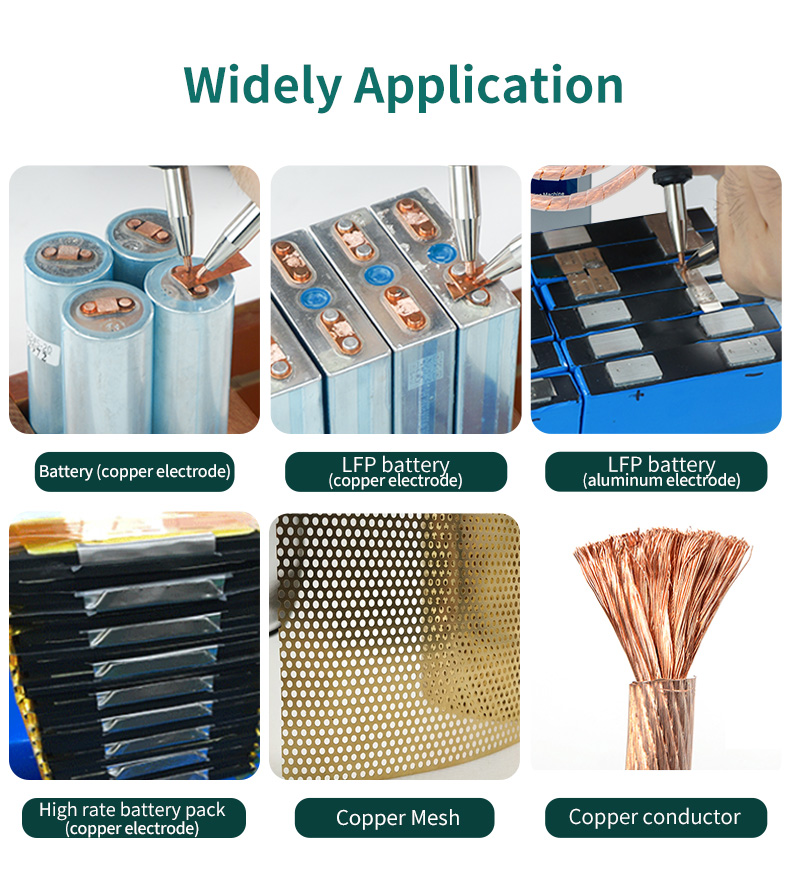

Ukuwelda kwiindawo ezithile kusetyenziswa kakhulu ukuwelda iipleyiti ezincinci. Le nkqubo ibandakanya ukunyanzeliswa kwangaphambili ukuqinisekisa unxibelelwano oluhle phakathi kwezinto zokusebenza; i-electrochemistry, eyenza umbindi otyhidiweyo kunye nendandatho yeplastiki kwindawo yokuwelda; kunye nokufakelwa kombane, okuvumela umbindi otyhidiweyo ukuba uphole kwaye uqine phantsi koxinzelelo oluqhubekayo ukuze wenze i-ai-weld exineneyo, enganciphiyo, engenazimfanta.

Umzekelo, iumthumeli webala lebhetrisisixhobo esikhethekileyo esisetyenziswa kwinkqubo yokwenza ibhetri ukuwelda iiseli zebhetri kunye neethebhu zokudibanisa, eziquka ikakhulu i-transformer, inkqubo yolawulo, izixhobo zokuwelda, inkqubo yokupholisa, njalo njalo. I-transformer isetyenziselwa ukunciphisa i-input voltage kunye nokunyusa umbane, inkqubo yolawulo ilawula ixesha lokuwelda kunye nombane wokuwelda, kwaye isebenzisa umgaqo wokuwelda okumelana nokuvelisa ubushushu obuphezulu kwindawo yokuwelda ukuze kufezekiswe ukuhlanganiswa kwesinyithi, ngaloo ndlela kugqityezelwa ukuwelda phakathi kweseli yebhetri kunye nenxalenye yokudibanisa.

Uphawu Lwethu:

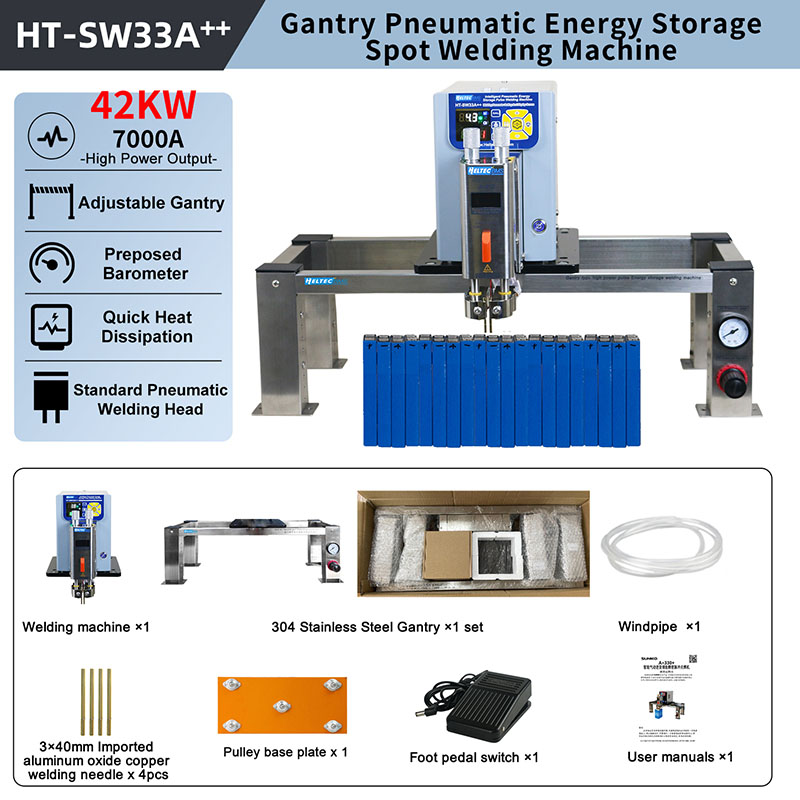

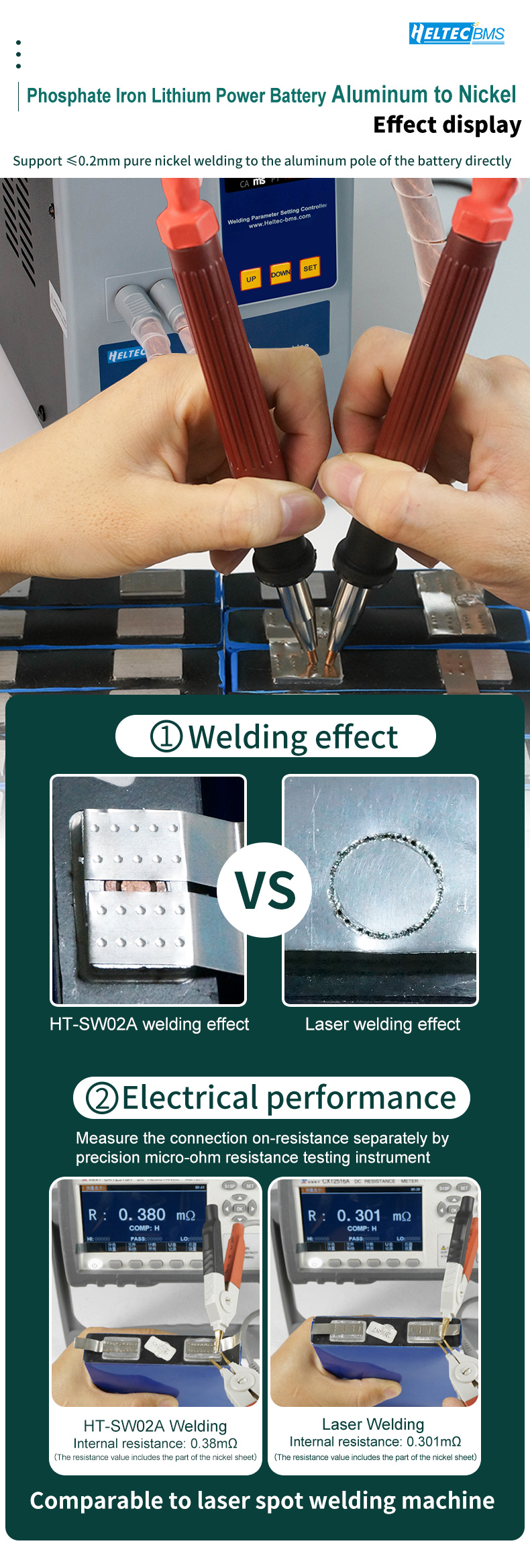

Sigxila kubuchwepheshe obuphambili bokuweldaoomatshini bokuwelda abanamandla aphezuluOkwangoku sigxile kwioomatshini bokuwelda be-capacitor yokugcina amandla, idibeneyooomatshini bokuwelda be-pneumatic,oomatshini bokuwelda beendawo zokugcina amandla omoya bohlobo lwe-gantry, njl. Xa kuthelekiswa nokuwelda okubandayo, iimveliso zethu zinamandla okuwelda aqinileyo. Xa kuthelekiswa netekhnoloji yokuwelda nge-laser, nangona ineenzuzo zokusebenza kakuhle kunye nokuchaneka okuphezulu, iimveliso zethu zinexabiso eliphantsi lezixhobo kunye neemfuno zobugcisa ezincinci kubaqhubi.

Isiphelo:

Oku kungasentla kukwazisa umgaqo wokusebenza kunye nokusetyenziswa komatshini wokuwelda amabala, ibhlog elandelayo siza kuqhubeka nokwazisa iimpawu kunye nokusetyenziswa kwawooomatshini bokuwelda be-capacitor yokugcina amandlakwayeumatshini wokuwelda indawo enomoya, nceda ujonge phambili kuyo!

Ukuba unemibuzo okanye ungathanda ukwazi okungakumbi, nceda ungathandabuzi ukubuzafikelela kuthi.

Ixesha lokuthumela: Novemba-15-2023