Intshayelelo:

Iibhetri zeLithiumluhlobo lwebhetri olusebenzisa isinyithi se-lithium okanye i-lithium alloy njengento engafanelekanga ye-electrode kwaye isebenzisa isisombululo esingenamanzi se-electrolyte. Ngenxa yeepropathi zemichiza esebenzayo ye-lithium metal, ukusetyenzwa, ukugcinwa, kunye nokusetyenziswa kwesinyithi se-lithium kuneemfuno eziphezulu kakhulu zokusingqongileyo. Okulandelayo, makhe sijonge i-homogenization, i-coating, kunye neenkqubo zokuqengqeleka ekulungiseleleni iibhetri ze-lithium.

I-homogenization ye-electrode enhle kunye nembi

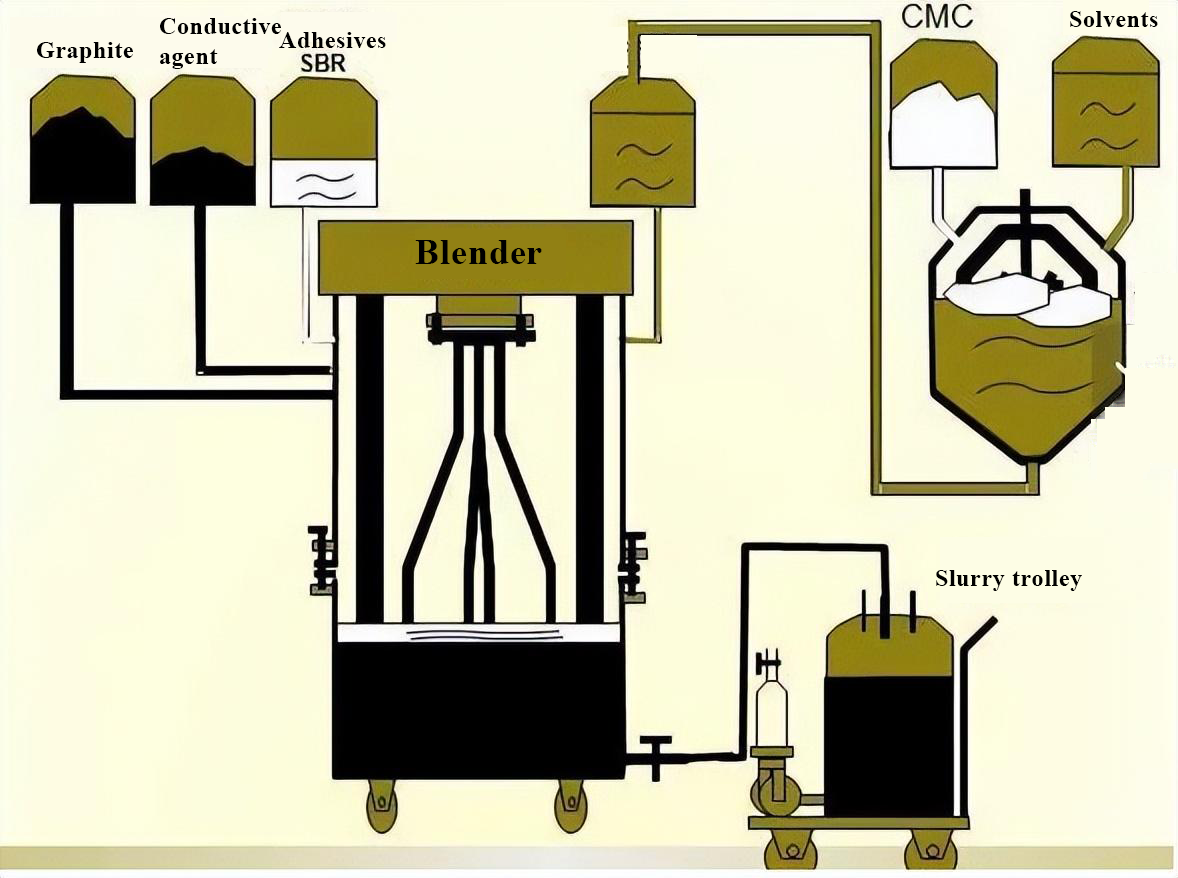

I-electrode yebhetri ye-lithium-ion iyona nto ibaluleke kakhulu kwiseli yebhetri. I-electrode positive and negative homogenization ibhekisela kwinkqubo yokulungiselela i-slurry efakwe kwii-electrode ezichanekileyo kunye ne-negative sheets ye-lithium ion. Ukulungiswa kwe-slurry kufuna ukuxuba izinto eziphathekayo ze-electrode, izinto ezingalunganga ze-electrode, i-agent conductive kunye ne-binder. I-slurry elungiselelwe kufuneka ibe yinto efanayo kwaye izinzile.

Abavelisi bebhetri be-lithium abahlukeneyo baneendlela zabo zenkqubo ye-homogenization. Umyalelo wokongeza izinto, umlinganiselo wokongeza izinto kunye nenkqubo yokuvuselela kwinkqubo ye-homogenization inefuthe elikhulu kwi-homogenization effect. Emva kwe-homogenization, i-slurry idinga ukuvavanywa kumxholo oqinileyo, i-viscosity, i-fineness, njl.

Ukwaleka

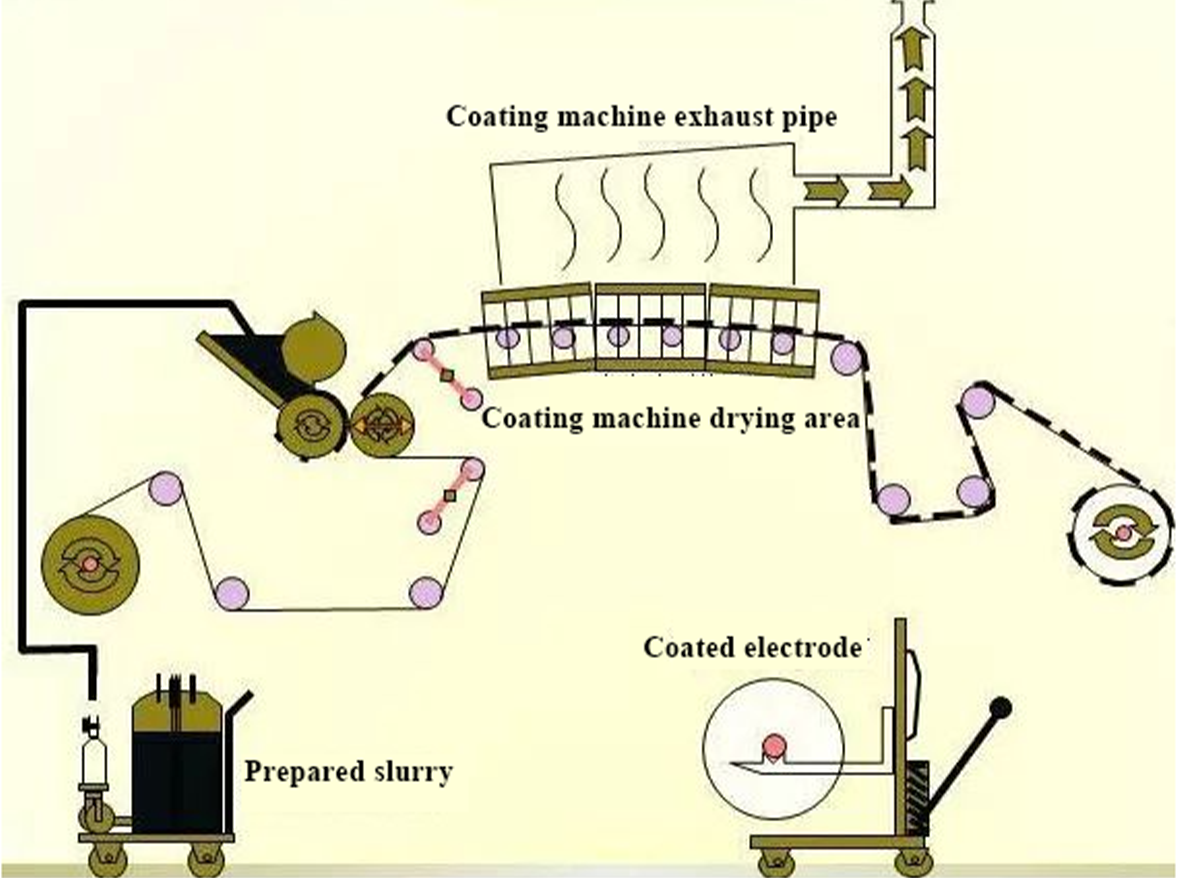

Inkqubo yokwaleka yinkqubo esekelwe kuphononongo lweepropati zolwelo, apho ulwelo olunye okanye ngaphezulu lufakwe kwi-substrate. I-substrate idla ngokuba yifilimu eguquguqukayo okanye i-backing paper, kwaye emva koko i-coating ye-coated liquid yomiswe kwi-oven okanye iphiliswe ukwenza ifilimu eneemisebenzi ekhethekileyo.

Ukwambathisa yinkqubo ephambili ekulungisweni kweeseli zebhetri. Umgangatho wokwaleka uhambelana ngokuthe ngqo nomgangatho webhetri. Ngelo xesha, iibhetri ze-lithium-ion zivakalelwa kakhulu kumswakama ngenxa yeempawu zenkqubo. Umkhondo wokufuma unokuba nempembelelo enkulu ekusebenzeni kombane webhetri; umgangatho wokusebenza kokugquma unxulumene ngokuthe ngqo nezalathi ezisebenzayo ezifana neendleko kunye nezinga lokufaneleka.

Inkqubo yokuvelisa ukutyabeka

I-substrate edibeneyo ikhutshwe kwisixhobo sokukhulula kwaye ifakwe kumatshini wokugubungela. Emva kokuba intloko kunye nomsila we-substrate zidibaniswe ukwenza ibhanti eqhubekayo kwitafile yokudibanisa, zondliwa kwisixhobo sohlengahlengiso lwe-tension kunye nesixhobo sokulungiswa kokuphambuka ngokuzenzekelayo ngesixhobo sokutsala, kwaye faka isixhobo sokugquma emva kokulungelelanisa ukunyanzeliswa kwendlela yephepha kunye nesikhundla somzila weshidi. I-pole piece slurry ifakwe kumacandelo kwisixhobo sokugquma ngokwexabiso lokutyabeka kwangaphambili kunye nobude obungenanto.

Xa i-coating emacala amabini, i-coating yangaphambili kunye nobude obungenanto bulandelelwa ngokuzenzekelayo ukugquma. I-electrode emanzi emva kokugquma ithunyelwa kumjelo wokumisa ukuze omiswe. Iqondo lokushisa lokumisa libekwe ngokuhambelana nesantya sokugquma kunye nobukhulu bokugquma. I-electrode eyomileyo ihlanganiswe emva kokulungiswa koxinzelelo kunye nokulungiswa kokuphambuka ngokuzenzekelayo kwisinyathelo esilandelayo sokucubungula.

Ukuqengqeleka

Inkqubo yokuqengqeleka kweentsimbi ze-lithium yebhetri yinkqubo yokuvelisa ecinezela ngokufanayo izinto ezikrwada ezifana nezixhobo ezisebenzayo, ii-conductive agents kunye nezibophelelo kwi-foil yensimbi. Ngokusebenzisa inkqubo yokuqengqeleka, isiqwenga sepali sinokuba nendawo ephezulu ye-electrochemical esebenzayo, ngaloo ndlela iphucula ukuxinana kwamandla kunye nokutshaja kunye nokukhupha ukusebenza kwebhetri. Kwangaxeshanye, inkqubo yokuqengqeleka inokwenza ukuba isiqwenga sepali sibe namandla aphezulu olwakhiwo kunye nokungaguquguquki okuhle, okunceda ukuphucula ubomi bomjikelezo kunye nokhuseleko lwebhetri.

Inkqubo yemveliso eqengqelekayo

Inkqubo yokuqengqeleka kwe-lithium yebhetri ye-pali iziqwenga ikakhulu ibandakanya ukulungiswa kwezinto ezikrwada, ukuxuba, ukudityaniswa, ukubunjwa kunye namanye amakhonkco.

Ukulungiswa kwemathiriyeli ekrwada kukuxuba imathiriyeli ekrwada ehlukeneyo ngokulinganayo kwaye wongeze isixa esifanelekileyo sesinyibilikisi sokuvuselela ukufumana udaka oluzinzileyo.

Ikhonkco lokuxuba kukudibanisa izinto ezahlukeneyo ezikrwada ngokulinganayo ukwenzela ukuxinana okulandelayo kunye nokubunjwa.

Ikhonkco lokudibanisa kukucinezela i-slurry ngokusebenzisa i-roller press ukwenzela ukuba iinqununu zezinto ezisebenzayo zifakwe ngokusondeleyo ukuze zenze isiqwenga se-pole kunye namandla athile okwakhiwa. Ikhonkco lokubumba kukuphatha i-pole piece kunye nobushushu obuphezulu kunye noxinzelelo oluphezulu ngokusebenzisa izixhobo ezifana nomshicileli oshushu ukulungisa imilo kunye nobukhulu beqhekeza.

.png)

Ukuqukumbela

Inkqubo yokulungiselela iibhetri ze-lithium inzima kakhulu, kwaye inyathelo ngalinye libalulekile. Gcina iliso kwibhlog ye-Heltec kwaye siya kuqhubeka nokuhlaziya ulwazi olufanelekileyo malunga neebhetri ze-lithium.

I-Heltec Energy liqabane lakho elithembekileyo kwimveliso yeebhetri. Ngokujolisa kwethu okungapheliyo kuphando kunye nophuhliso, kunye noluhlu lwethu olubanzi lwezincedisi zebhetri, sinikezela ngezisombululo zokuphela konyaka ukuhlangabezana neemfuno eziguqukayo zeshishini. Ukuzibophelela kwethu ekugqweseni, izisombululo ezilungiselelweyo, kunye nentsebenziswano eyomeleleyo yabathengi kusenza ukuba sikhethe ukukhetha abavelisi beebhetri kunye nababoneleli kwihlabathi liphela.

Ukuba unayo nayiphi na imibuzo okanye ungathanda ukufunda ngakumbi, nceda ungalibazisifikelela kuthi.

Isicelo seNtelekelelo yeendleko:

UJacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Ixesha lokuposa: Oct-23-2024