Intshayelelo:

Ibhetri yeLithiumibhetri etshajwayo kunye ne-lithium njengeyona nto iphambili. Isetyenziswa ngokubanzi kwizixhobo zombane ezahlukeneyo kunye nezithuthi zombane ngenxa yobuninzi bamandla, ubunzima obulula kunye nobomi bomjikelo omde. Ngokumalunga nokusetyenzwa kweebhetri ze-lithium, makhe sijonge kwiinkqubo ze-spot welding, ukubhaka okungundoqo kunye nenaliti yolwelo yeebhetri ze-lithium.

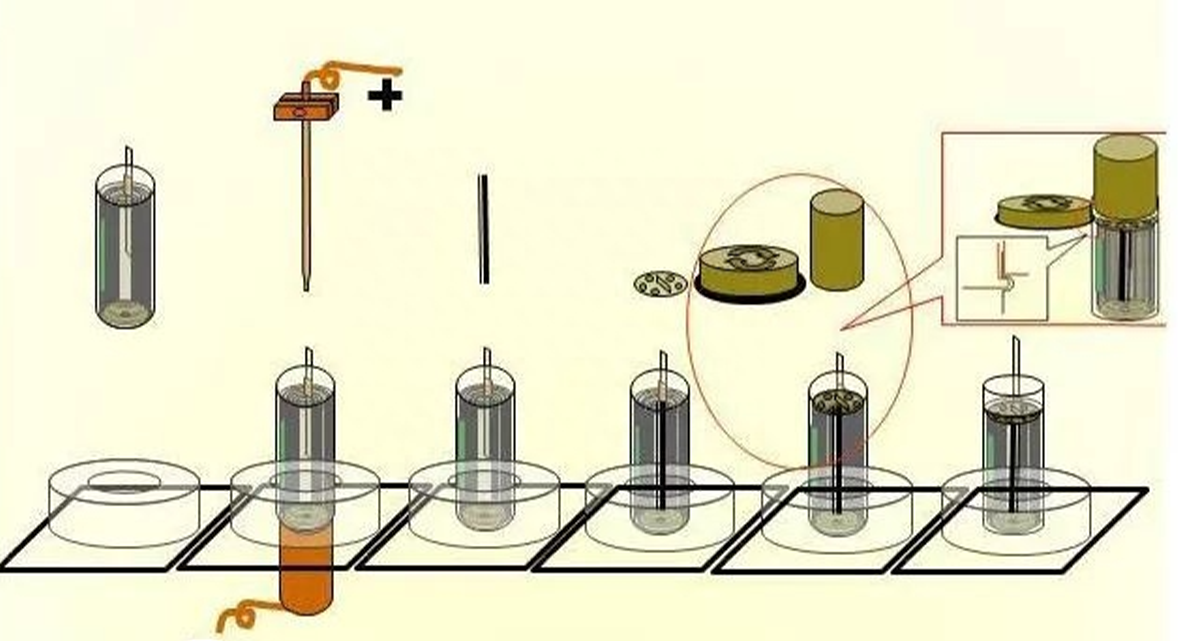

Ukuwelda indawo

I-Welding phakathi kwezibonda zeebhetri ze-lithium kunye naphakathi kweepali kunye nomqhubi we-electrolyte yenye yeenkqubo ezibalulekileyo kwi-lithium yokuvelisa ibhetri. Umgaqo wayo oyintloko kukusebenzisa i-high-frequency pulse arc ukufaka i-high-frequency high-temperature kunye ne-high-voltage yangoku phakathi kwepali kunye nomqhubi we-electrolyte, ukwenzela ukuba i-electrode kunye ne-lead inyibilike ngokukhawuleza kwaye yenze uxhumano oluqinileyo. Ngethuba lenkqubo ye-welding, iiparamitha ze-welding ezifana nobushushu be-welding, ixesha, uxinzelelo, njl.

Ukuwelda indawoyindlela yemveli yokuwelda kwaye ngoku yeyona ndlela isetyenziswa kakhulu. Ukusebenzisa umgaqo wokumelana nokufudumala, i-welding material iyatshisa kwaye iyancibilika ngokusebenzisana kwangoku kunye nokuchasana, ukwenza uxhumano oluqinileyo. I-Spot welding ifanelekile ukuveliswa kwezinto ezinkulu zebhetri, ezifana neebhetri zemoto zombane, iibhetri zokugcina amandla, njl.

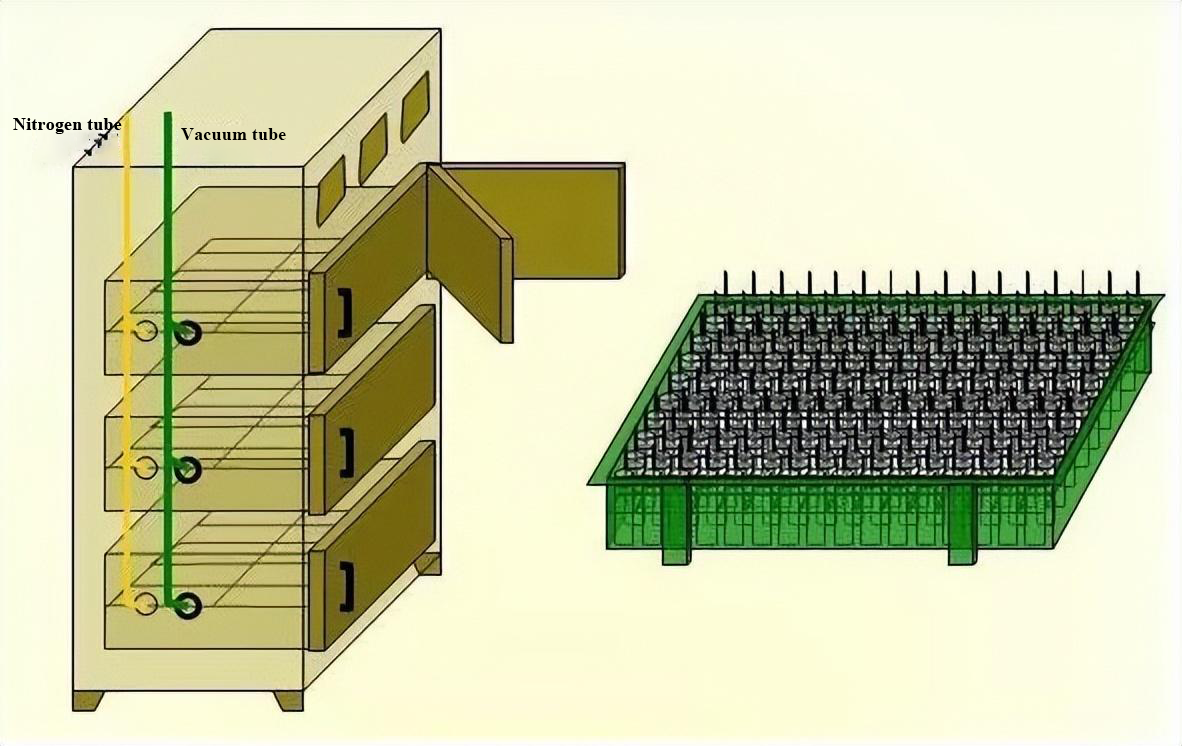

Ukubhaka iiseli zebhetri

Ukubhaka kudlala indima ebalulekileyo kwimvelisoibhetri ye-lithiumiiseli. Umxholo wamanzi emva kokubhaka uchaphazela ngokuthe ngqo ukusebenza kombane. Inkqubo yokubhaka isemva kwendibano ephakathi naphambi kokujova ulwelo kunye nokupakishwa.

Inkqubo yokubhaka ngokubanzi ithatha indlela yokubhaka i-vacuum, ukupompa i-cavity kuxinzelelo olubi, kwaye emva koko ukufudumala kwiqondo lokushisa elithile lokubhaka i-insulation. Ubumanzi obungaphakathi kwe-electrode busasazeka kumphezulu wento ngokwahlukana koxinzelelo okanye umahluko wokuxinana. Iimolekyuli zamanzi zifumana amandla aneleyo e-kinetic kumphezulu wento, kwaye emva kokoyisa umtsalane we-intermolecular, zibalekela kuxinzelelo oluphantsi lwegumbi lokucoca.

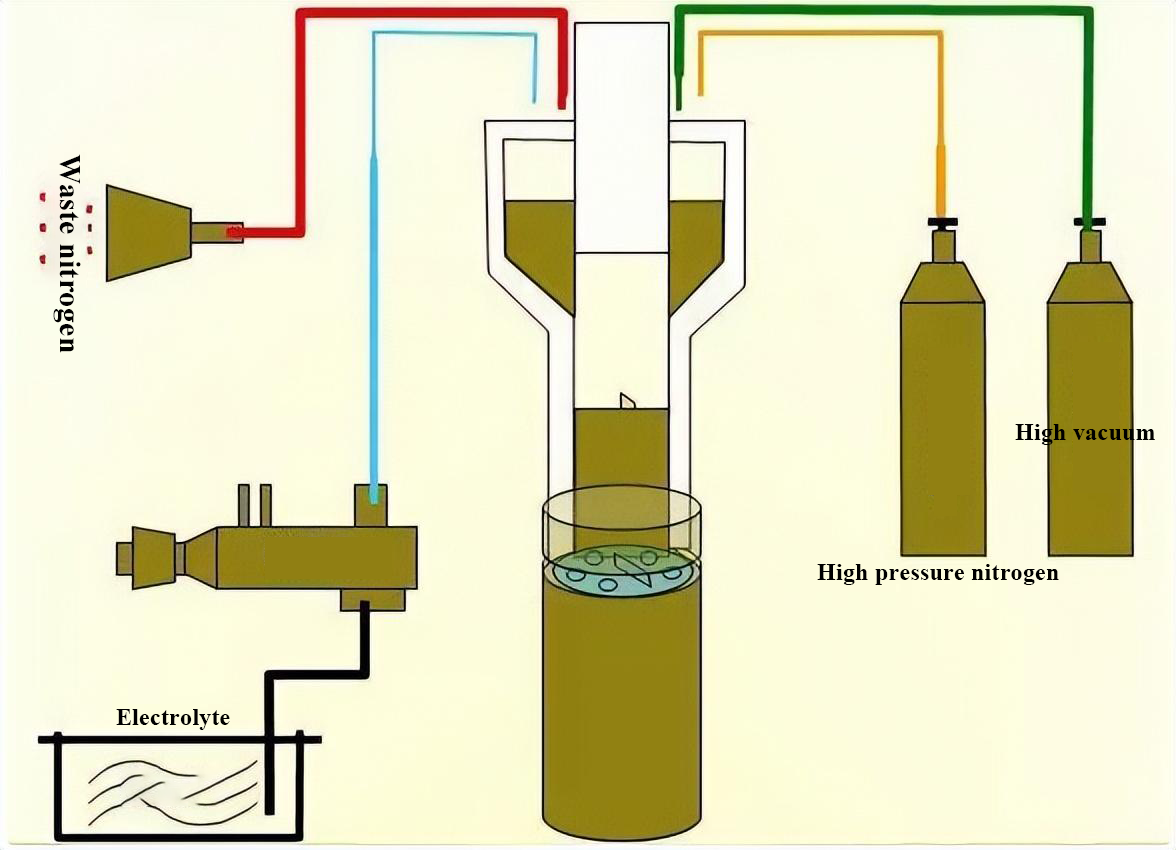

Isitofu

Indima yeibhetri ye-lithiumI-electrolyte kukuqhuba ii-ion phakathi kwee-electrode ezilungileyo nezingalunganga, kwaye zisebenze njengesixhobo sokutshaja kunye nokukhupha, njengegazi lomntu. Indima ye-electrolyte kukuqhuba i-ion, ukuqinisekisa ukuba ii-ion zihamba ngesantya esithile phakathi kwee-electrode ezilungileyo kunye ne-negative ngexesha lokutshaja kwebhetri kunye nenkqubo yokukhupha, ngaloo ndlela yenze yonke i-loop yesiphaluka ukuvelisa okwangoku.

Isitofu sinempembelelo enkulu ekusebenzeni kweseli yebhetri. Ukuba i-electrolyte ayingenanga kakuhle, iya kubangela ukungasebenzi kakuhle komjikelo weeseli zebhetri, ukusebenza kakubi kwesantya, kunye nokutshaja i-lithium deposition. Ngoko ke, emva kwesitofu, kuyimfuneko ukuma kwiqondo lokushisa eliphezulu ukuvumela i-electrolyte ukuba ingene ngokupheleleyo kwi-electrode.

Inkqubo yokuvelisa isitofu

Isitofu kukuqala ngokukhupha ibhetri kwaye usebenzise umahluko woxinzelelo phakathi kwangaphakathi nangaphandle kweseli yebhetri ukuze uqhube i-electrolyte kwiseli yebhetri. Inaliti ye-Isobaric kukusebenzisa kuqala umgaqo woxinzelelo oluhlukileyo ukutofa ulwelo, kwaye emva koko uhambise iseli yebhetri etofiweyo kwisikhongozeli soxinzelelo oluphezulu, kunye nokumpompa uxinzelelo olungalunganga/uxinzelelo olulungileyo kwisikhongozeli ukuze sijikelezwe ngendlela engatshintshiyo.

I-Heltec inikezela ngeentlobo ezahlukeneyo zokusebenza okuphezuluamabala abawelderyenzelwe ngokukodwa ukuwelda intsimbi yebhetri. Ukusebenzisa itekhnoloji yokumelana ne-welding ephezulu, inesantya esikhawulezayo sokuwelda kunye namandla aphezulu e-weld, alungele iibhetri ze-welding kunye neemveliso zombane. Ukuxhotyiswa ngenkqubo yokulawula ehlakaniphile, abasebenzisi banokuhlengahlengisa ngokulula iiparitha ze-welding ukuqinisekisa umgangatho we-welding ongaguqukiyo. Uluhlu lwethu lwee-welders ze-spot luhlangene kwaye lusebenza lula, lunceda ukuphucula ukusebenza kakuhle kwemveliso kunye nokunciphisa ukusetyenziswa kwamandla. Sikhethe ukuba sikuncede ufezekise izisombululo ze-welding ezisebenzayo!

Ukuqukumbela

Inyathelo ngalinye kwiibhetri ye-lithiuminkqubo yokucubungula kufuneka ilawulwe ngokungqongqo ukuqinisekisa ukhuseleko kunye nokusebenza kwemveliso yokugqibela. Ngokuhambela phambili kwetekhnoloji, iinkampani ezininzi zihlala zijonga izinto ezintsha kunye neenkqubo zokuphucula ukuxinana kwamandla kunye nobomi benkonzo yeebhetri.

I-Heltec Energy liqabane lakho elithembekileyo kwimveliso yeebhetri. Ngokujolisa kwethu okungapheliyo kuphando kunye nophuhliso, kunye noluhlu lwethu olubanzi lwezincedisi zebhetri, sinikezela ngezisombululo zokuphela konyaka ukuhlangabezana neemfuno eziguqukayo zeshishini. Ukuzibophelela kwethu ekugqweseni, izisombululo ezilungiselelweyo, kunye nentsebenziswano eyomeleleyo yabathengi kusenza ukuba sikhethe ukukhetha abavelisi beebhetri kunye nababoneleli kwihlabathi liphela.

Ukuba unayo nayiphi na imibuzo okanye ungathanda ukufunda ngakumbi, nceda ungalibazisifikelela kuthi.

Isicelo seNtelekelelo yeendleko:

UJacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Ixesha lokuposa: Nov-01-2024