Intshayelelo:

Oomatshini bokuwelda indawo yebhetrizizixhobo ezibalulekileyo kwimveliso kunye nokudibanisa iipakethi zebhetri, ngakumbi kwisithuthi sombane kunye namacandelo amandla ahlaziyekayo. Ukuqonda umgaqo wabo wokusebenza kunye nokusetyenziswa ngokufanelekileyo kunokwandisa kakhulu ukusebenza kunye nomgangatho wokuhlanganisa ibhetri.

IBattery Spot Welding Machine Umgaqo wokuSebenza

Ukuwelda indawo yebhetri yinkqubo edibanisa imiphezulu yentsimbi emibini okanye ngaphezulu kunye ngokufaka ubushushu kunye noxinzelelo. Oku kuphunyezwa ngokusetyenziswa kombane ohamba phakathi kwezinto zokusebenza. Amalungu asisiseko aumatshini wokuwelda indawoziquka:

1. Ii-Electrodes: Ezi ziqhele ukwenziwa ngobhedu kwaye zisetyenziselwa ukuqhuba umbane kwizinto ezidityanisiweyo. Uyilo lwee-electrodes lunokwahluka ngokuxhomekeke kwisicelo esithile kunye nohlobo lweentsimbi ezidityanisiweyo.

2. I-Transformer: I-transformer inciphisa i-voltage ephezulu ukusuka kumthombo wamandla ukuya kumbane ophantsi ofanelekileyo kwinkqubo ye-welding ngelixa inyusa ngoku.

3. Inkqubo yokulawula: Oomatshini bokudibanisa amabala banamhlanje baxhotyiswe nge-microcontrollers ezivumela ulawulo oluchanekileyo kwiiparamitha ze-welding, njengangoku, ixesha kunye noxinzelelo.

Inkqubo iqala xa i-electrodes ibekwe kwindawo ukuze i-welded. Umsinga ugqithiswa kwii-electrodes, uvelisa ubushushu ngenxa yokunganyangeki kombane kwi-interface yeentsimbi. Obu bushushu bunyusa ubushushu bufikelele kwindawo yokunyibilika kwezinto, kubangele ukuba zidibane. Uxinzelelo olusetyenziswe ngama-electrodes lunceda ukuqinisekisa ukuba ibhondi eyomeleleyo ngokunciphisa ukubunjwa kwe-oxides kwi-joint.

Emva kwexesha elifutshane lokupholisa, umdibaniso odibeneyo uqina, obangela uxhulumaniso oluqinileyo lomatshini. Yonke le nkqubo idla ngokukhawuleza kakhulu, ithatha nje iqhezu lomzuzwana.

Iindlela zokusetyenziswa komatshini wokuwelda ibhetri Spot

- Ukulungiselela

Ngaphambi kokusebenzisa aumatshini wokuwelda indawo yebhetri, kubalulekile ukulungiselela indawo yokusebenza kunye nemathiriyeli:

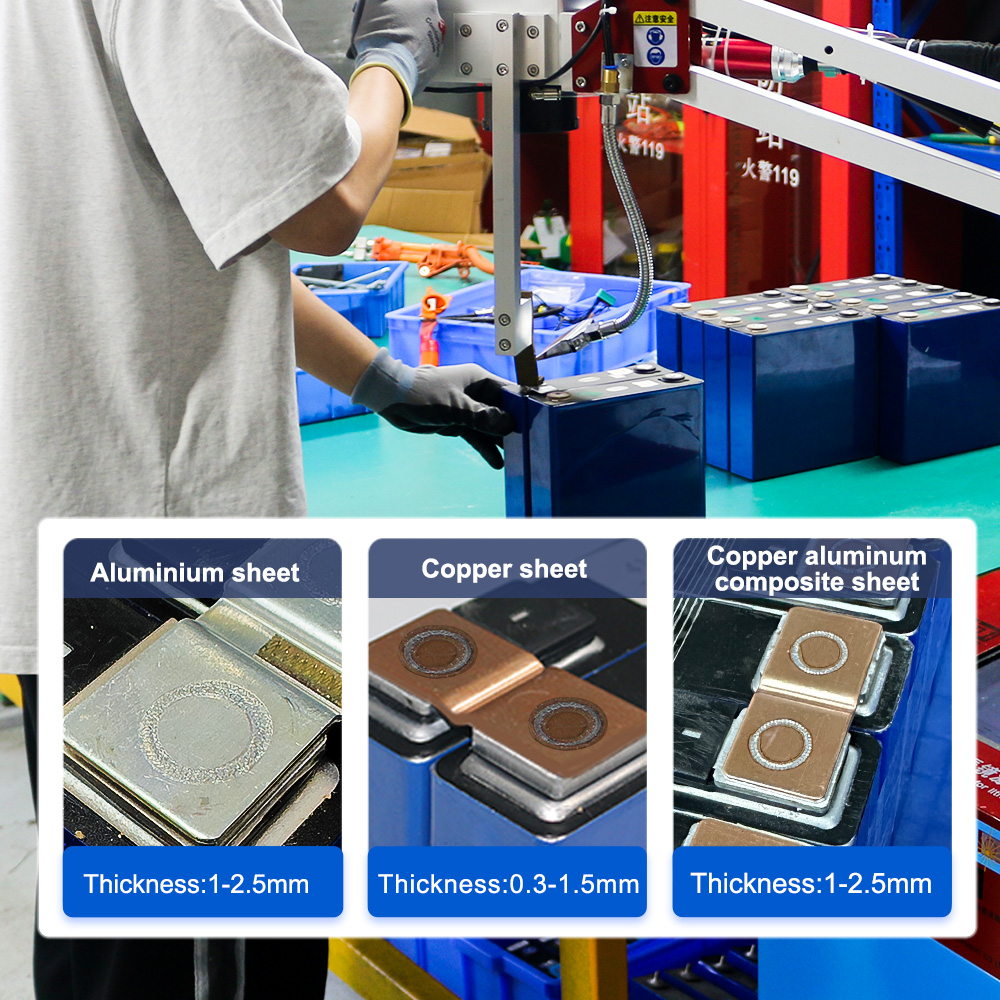

1. Ukukhethwa kwezinto: Qinisekisa ukuba isinyithi esidityanisiweyo siyahambelana. Izinto eziqhelekileyo zokudibanisa ibhetri ziquka i-nickel-plated steel kunye ne-aluminium.

2. Ukucocwa koMphezulu: Coca imiphezulu ukuze idityaniswe ukususa naziphi na izinto ezingcolisa, ezifana negrisi, ubumdaka, okanye i-oxidation. Oku kunokwenziwa ngokusebenzisa izinyibilikisi okanye izinto ezirhabaxa.

3. Ukuseta izixhobo: Misa ngokufanelekileyo umatshini ngokwemiyalelo yomenzi. Oku kubandakanya ukulungiswa kwee-electrode kunye nokuqinisekisa ukuba zonke iimpawu zokhuseleko ziyasebenza.

- Umatshini we-Spot WeldingInkqubo yeWelding

1. Ukuma: Beka iiseli zebhetri kunye nemicu yokuqhagamshela kwindawo echanekileyo phakathi kwee-electrode. Qinisekisa ukuba zilungelelaniswe ukuphepha nakuphi na ukungahambi kakuhle ngexesha lenkqubo ye-welding.

2. Ukubeka iiParameters: Lungisa iiparitha ze-welding kwinkqubo yokulawula, kubandakanywa ukuqina kwangoku, ixesha le-welding, kunye noxinzelelo. Ezi seto zinokwahluka ngokusekelwe kwizinto kunye nobukhulu obudityanisiweyo.

3. Welding: Vuselela umatshini ukuqalisa inkqubo welding. Ukubeka iliso ekusebenzeni ukuqinisekisa ukuba i-electrode igcina uqhagamshelwano olufanelekileyo kunye nokuba i-current ihamba ngokuchanekileyo.

4. Ukuhlolwa: Emva kwe-welding, jonga ngokubonakalayo amajoyina kuzo naziphi na iziphene, ezifana nokudityaniswa okungaphelelanga okanye i-spatter eninzi. Ezinye izicelo zinokufuna uvavanyo olongezelelweyo lokuqhubekeka kombane okanye amandla omatshini.

Iingqwalasela zoKhuseleko

Ukusebenza kunyeoomatshini bokuwelda amabalainokubangela iingozi ezithile. Ngalo lonke ixesha ulandela imigaqo yokhuseleko:

1. Izixhobo zoKhuseleko: Nxiba izixhobo ezifanelekileyo zokuzikhusela (PPE), kuquka iiglavu, iindondo zokhuseleko, neefaskoti zokukhusela kwiintlantsi nobushushu.

2. Ukungenisa umoya: Qinisekisa ukuba indawo yokusebenzela inomoya owaneleyo ukuphepha ukuphefumla nayiphi na imisi eveliswa ngexesha lenkqubo ye-welding.

3. Iinkqubo eziNgxamisekileyo: Ziqhelanise neenkqubo zokuvala isantya sikaxakeka kwaye uqinisekise ukuba umatshini uneendawo zokumisa zikaxakeka ezifikelelekayo.

Ukuqukumbela

Oomatshini bokuwelda indawo yebhetriidlala indima ebalulekileyo ekudibaneni kakuhle kweepakethi zebhetri. Ukuqonda umgaqo wabo wokusebenza kunye nokulandela iindlela ezifanelekileyo zokusetyenziswa kunokukhokelela kwi-welds ekumgangatho ophezulu kunye nemveliso eyandisiweyo. Ngokubeka phambili ukhuseleko kunye nolungiselelo, abaqhubi banokusebenzisa ngempumelelo aba matshini kwizicelo ezahlukeneyo, befaka igalelo ekuphuculweni kobugcisa bokugcina amandla.

Ukuba unombono wokudibanisa ibhetri ngokwakho, ukuba ujonge i-welder yendawo echanekileyo ephezulu yebhetri yakho yokutshisela, ke indawo ye-welder evela kwi-Heltec Energy ifanelekile ukuba uyiqwalasele.

Ukuba unayo nayiphi na imibuzo okanye ungathanda ukufunda ngakumbi, nceda ungalibazisifikelela kuthi.

Isicelo seNtelekelelo yeendleko:

UJacqueline:jacqueline@heltec-energy.com/ +86 185 8375 6538

Sucre:sucre@heltec-bms.com/ +86 136 8844 2313

Nancy:nancy@heltec-energy.com/ +86 184 8223 7713

Ixesha lokuposa: Sep-20-2024